- Tube Ice Plant Solution

- Aluminum Direct Cooling Block Ice Plant Solution

- Brine Cooling Block Ice Plant Solution

- Flake Ice Plant Solution

- Artificial Skiing Ground Solution

- Chemical Reactor Cooling Solution

- Concrete Cooling Solution

- Edible Ice Station Solution

- Mine Cooling Solutions

Contact Us

- +86 21 57456563

- +86 21 57456583

- inquiry@linskyice.com

Man-made skiing ground is made by ice machine. After crushed into powder, ice will be delivered and put flat on the slide-way to form an artificial skiing ground. Slide way can be set up inside room or on mountain etc outdoor sites. Various ice machines e.g. flake ice machine, tube ice machine, plate ice machine and block ice machine all could be used in man-made snow making system, but nowadays extensively used one is flake ice machine.

*Linsky man-made skiing ground

Linsky Flake Ice Machine Snow Making System

Flake ice machine produces 2mm thick thin pieces of ice. Adopt rotary ice blade so that ice is dry and can be easily crushed into powder. As freeze by low temperature, ice looks white and very close to snow color. What's more, sub-cooled temperature makes it not easy to melt.

Major parts for a typical flake ice plant: containerized flake ice machine, containerized automatic ice storage, blowing ice conveyor system.

1. Containerized flake ice machine

Containerized flake ice machine can be put into use very conveniently. All necessary parts of a flake ice pant are installed in container. It's easy for movement and ready to use without setting up any protection. It starts operation as soon as water and electricity plug in. The max ice capacity of a 40'HQ container is 60T/day.

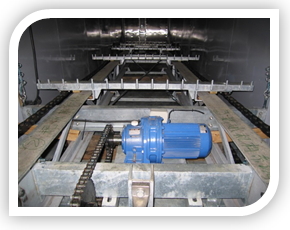

*inside of a containerized flake ice machine

2. Containerized rake type automatic ice storage

Containerized rake type automatic ice storage pave ice flake flat inside of ice storage and could load ice at max capacity. It can convey ice to the ice outlet according to actual ice demand. It is usually installed under containerized flake ice machine. The ice flakes produced by ice machine falls off into containerized rake type automatic from the bottom of ice making equipment. Because it is equipped with refrigeration unit, so the ice storage temperature is kept below -10°C, which can always keep ice flake dry. The rake teeth of automatic ice storage can further crush ice flake into powder and forms the 'snow'.

*Linsky rake type automatic ice storage

The max capacity of ice storage in a 40'HQ container is 20T.

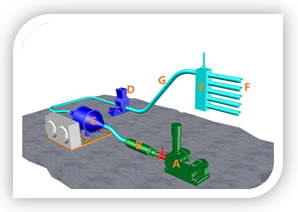

3. Blowing ice conveyor system

Blowing ice conveyor system is commonly used for ice delivery. Snow making system, under normal circumstance, would be installed on the upper position of the rail. The principle of blowing ice conveyor system is that the air will be compressed into low temperature, high pressure and high speed air current then flowing at high speed in the pipe. It is the blast of strong air current that take the ice to different sites in skiing ground. The max distance of bowing ice conveyor system could reach over 500 meters, with max lifting distance up to 10 meters.

Main parts for blowing ice conveyor system

*blowing ice conveyor system

Roots blower: similar principle as compressor, which supplies high pressure compressed air;

*blowing ice conveyor system

Deafener: roots blower will cause big noise so shall be equipped with a deafener;

Air-cooler: cool high-temperature & high-pressure compressed air instantly to 0°C, which ensures ice will not melt;

*air-cooler

Airlock rotary valve: ensure no outer air enter into ice hopper that ice could mix with the low temperature air current of high pressure, high speed in the pipe line;

*airlock rotary valve

Shunt Valve: It is driven by reducer and control ice to different ice delivery pipes lines.

Copyright © All rights are reserved by Linsky• Formulate future since 2004