- Tube Ice Plant Solution

- Aluminum Direct Cooling Block Ice Plant Solution

- Brine Cooling Block Ice Plant Solution

- Flake Ice Plant Solution

- Artificial Skiing Ground Solution

- Chemical Reactor Cooling Solution

- Concrete Cooling Solution

- Edible Ice Station Solution

- Mine Cooling Solutions

Contact Us

- +86 21 57456563

- +86 21 57456583

- inquiry@linskyice.com

Tube ice plant handles all activities including the production, storage, transportation, wholesale and retail of tube ice. The capability of a typical tube ice plant can be planned as much as 10~200ton/day but shall be based on the surrounding environment and the actual demand. Larger ice production factory also can be designed as per client's requirement.

The advantages of tube ice plant

- Automatic operation with other associated equipment could realize an automation of ice storage and ice package, thus labor cost is largely saved;

- SUS304 evaporator complies with food sanitary requirement, hence ice tube can be eaten directly or mix with food, beverage and drinks. It belongs to high value ice;

- Ice tube is widely used in human consumption so the tube ice has big market potential;

- Vertical evaporator requires small use space and saves initial investment of an ice plant

- Ice tube can be put into mass production;

- Fast return on investment like that 1~2 years can pay for itself.

Target customers of tube ice plant

- Edible ice: Linsky tube ice is edible and extensively applicable in bars, hotels, stores and smoothie making;

- Ice in chemical reaction cooling: as much chemical material will produce exothermic chemical reaction in their mixing process, to prevent temperature runaway would happen, chemical plant usually put ice tube or other ice into the reactor;

- Ice in fishing vessels: fishing vessels usually go out for fishing after charging full ice at dock. Seafood must be covered with ice immediately after catching to ensure its freshness.

Factors when you considering a tube ice plant

- Considering transportation cost, the optimum ice distribution distance is suggested within 30km. It would better to build an ice plant near your customer group;

- Tube ice plant needs relative large capacitance. Equipped with capacitance of 3.5KVA per tonnage, and it is suggested to choose the location with time-of-use electricity price;

- Tube ice plant should have sufficient and clean water supply, ice could be eaten only after by using RO system;

- Location is not to approach residential area because compressor, cooling tower and ice hoisting device could probably produce noise;

- Need to contact with your contractor about ice plant land use, especially for the second even third stage plan;

- Ice tube packed and distributed by cold chain to needed areas.

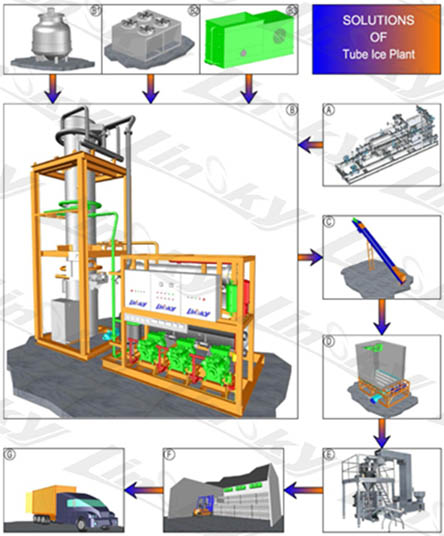

Solution to a typical tube ice plant

A: RO system

B: Tube ice machine

B1: Cooling tower

B2: Air-cooled condenser

B3: Evaporative-cooled condenser

C: Screw ice conveying system

D: Screw type automatic ice storage

E: Multi-hoppers weighing and packing machine

F: Ice storage

G: Cold chain van

Ice could be directly eaten only after water be filtered and sterilized by RO system A;

Tube ice machine B has three cooling methods, respectively are cooling tower water-cooled system B1, air-cooled system B2, evaporative-cooled system B3;

After produced by tube ice machine B, ice tube will be transported by screw ice conveying system C to screw type automatic ice storage D;

Screw type automatic ice storage D works only as tube ice buffer storage and could store 1/2 of daily capacity ice production, thus ice could be packed every 12 hrs. It can also automatically deliver ice to the multi-hoppers weighing and packing machine for precise packaging then ice packs can be stacked on the pallets. Forklift takes the pallets to the ice storage F, when ice is in need pallet can be transferred directly to the cold chain van G.

Linsky could tailor made tube ice plant solutions and investment feasibility proposal according to clients land, capacity and local weather conditions.

Copyright © All rights are reserved by Linsky• Formulate future since 2004