- Tube Ice Plant Solution

- Aluminum Direct Cooling Block Ice Plant Solution

- Brine Cooling Block Ice Plant Solution

- Flake Ice Plant Solution

- Artificial Skiing Ground Solution

- Chemical Reactor Cooling Solution

- Concrete Cooling Solution

- Edible Ice Station Solution

- Mine Cooling Solutions

Contact Us

- +86 21 57456563

- +86 21 57456583

- inquiry@linskyice.com

Flake ice plant handles all activities including the production, storage, transportation, wholesale and retail of ice flake. Many applications are in need of flake ice such as in chemical industry, mining industry, nuclear power plant, concrete mix station, supermarket etc.

The advantages of flake ice plant

- Automatic operation with other associated equipment could realize automatic ice storing, delivering and packaging etc functions;

- SUS304 or chromed evaporator complies with food sanitary requirement;

- Thin piece ice, no need of crushing;

- Continuous ice making process and ice can be get in 2 min after plug in;

- Ice flake can be put into mass production reaching a capacity to thousands of tons per day;

Target customers of flake ice plant

- Ice in supermarket/grocery market: flake ice is similar to snow shape, mainly used for seafood preservation in supermarket;

- Ice in chemical reaction cooling: as much chemical material will produce exothermic chemical reaction in their mixing process, to prevent temperature runaway would happen, chemical plant usually put ice flake or other ice into the reactor.

- Ice in concrete cooling: cement, sand and gravel reaches high temperature under sun exposure, which will produce a large amount of chemical reaction heat in concrete mixing process. The control of concrete mixing temperature is essential for concrete quality.

- Ice in mine cooling: Every 100 meters down the mine, the temperature increases by 2℃; when land surface temperature is 30℃, the temperature of the mine at 1000 meters below can reach to 50℃. To alleviate underground drain problem, ice flake is applied in quantities to cool down the underground working environment;

- Ice in man-made snow scene: flake ice is thin, crisp, with milky white color very similar to snow. After crushed, flake ice is laid fat on the ground by using ice conveying system and thus will gradually form an artificial skiing ground; or by spraying in the air and stimulate the snow falling scene;

- Ice in fishing vessels: fishing vessels usually go out for fishing after charging full ice at dock. Seafood must be covered with ice immediately after catching to ensure its freshness

Factors when you considering a flake ice plant

- Consider the matching issues to the ice making equipment, try to locate ice machine near reactor, mixer etc.;

- Flake ice plant needs relative large capacitance. Equipped with capacitance of 3.5KVA per tonnage, and it is suggested to choose the location with time-of-use electricity price;

- Flake ice can be delivered by multiple kinds of ice conveyors such as air, screw, crawler and more, choose a suitable one will increase system reliability;

- For long-term storage, it is suggested to use ice storage with crushing device to avoid ice lump, for example rake type automatic ice storage, screw type automatic ice storage and crawler type automatic ice storage;

- Location try not to approach residential area cause compressor, cooling tower and ice hoisting device could probably cause noise pollution;

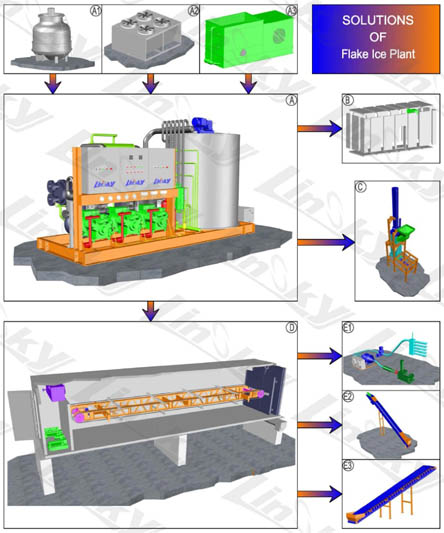

Solutions to a typical flake ice plant

A: Flake ice machine

A1: Cooling tower

A2: Air-cooled condenser

A3: Evaporative condenser

B: Common ice storage

C: Ice compactor

D: Rake type automatic ice storage

E1: Blowing ice conveyor

E2: Screw ice conveyor

E3: Crawler ice conveyor

Flake ice machine A can adopt three cooling methods, respectively are cooling tower system A1, air-cooled condenser A2, evaporative-cooled condenser A3.

Common ice storage B is usually installed under flake ice machine A. The ice flake produced by ice machine falls off into ice storage B from the bottom of flake ice machine evaporator. This plan fit for small capacity flake ice plant.

Rake type automatic ice storage D is installed under flake ice machine A. The ice flake produced by ice machine falls off into ice storage D from the bottom of flake ice machine evaporator. The ice layer can be automatically paved smoothly by the rake meanwhile the height of rake will be adjusted automatically according to the actual ice level, finally automatically conveys ice to the ice outlet etc. The outlet to the rake type automatic ice storage D could connect to blowing ice conveyor E1, screw ice conveyor E2, or crawler ice conveyor E3 and send ice to needed place.

Flake ice can be directly put into ice compactor C to compress into various sizes of ice block.

Linsky could tailor made flake ice plant solutions and investment feasibility proposal according to clients land, capacity and local weather conditions.

Copyright © All rights are reserved by Linsky• Formulate future since 2004