Contact Us

- +86 21 57456563

- +86 21 57456583

- inquiry@linskyice.com

Linsky has extensive experience in the design, manufacture and trade of tube ice machine. This year, we have led the way with significant innovations on commercial use tube ice maker.

Tube Ice hollow cylindrical ice shape with three standard specifications for your options:

Tube Ice hollow cylindrical ice shape with three standard specifications for your options:

Option 1: external Ø 35mm,internal Ø 8-18mm,length 35-50mm;

Option 2: external Ø 29mm,internal Ø 6-16mm,length 30-45mm;

Option 3: external Ø 25mm,internal Ø 2-12mm,length 25-35mm;

Features Tube ice is thick and transparent with long storage period. It isn't likely to melt in short time and has good air permeability.

Application drinks mix/ decoration, keeping vegetable and seafood fresh, all industries etc.

Tube Ice Machine Features

- Tube ice machine, operates on an intermittent cycle, for example 18 minutes ice making and 3 minutes ice harvesting per cycle based on external diameter of 35mm specification ice tube;

- The internal diameter of tube ice can be adjusted according to ice making time;

- The evaporator employs SUS304 material and the heat exchange tube is designed at the most optimized thickness, combined with specialized heat treatment processing technology, which makes the best use of heat conductibility;

- Stainless steel cutters driven by gear motors are uniquely designed to produce cylindrical ice;

- High quality stainless steel for all water and ice contacting surfaces which are corrosion resistant and easy to clean;

- Tube ice machine is furnished with sub cooler, which ensures the energy efficiency of the system and gets the higher C.O.P;

- Rapid harvest and quick recovery due to hot gas defrost;

- Highly efficient Bitzer piston compressor;

- Self-diagnostic indicator light and electronic temperature controls;

- Warranty period

| Complete Package | 12~15 months |

| Compressor | 3 years |

| Evaporator | 3 years |

| Condenser | 3 years |

| Cooling Tower | 15 months |

How Does A Tube Ice Machine Work?

|

|

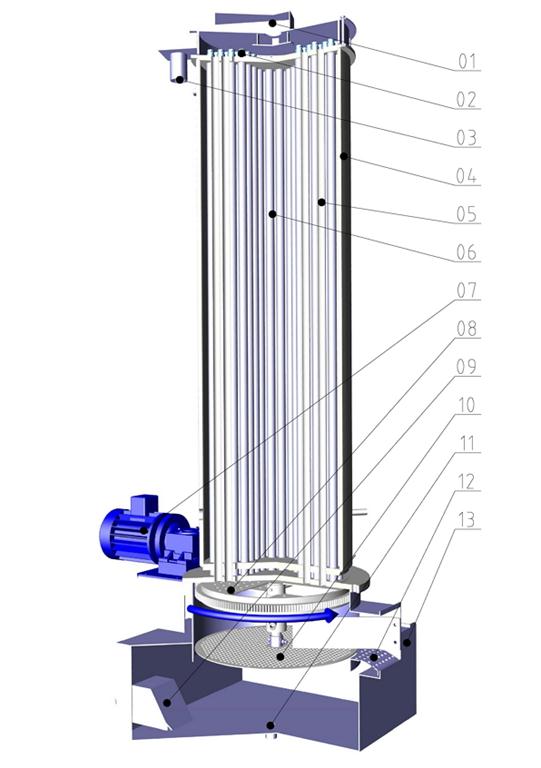

* The diagram of tube ice machine working principle

Ice making process

As shown, when refrigeration system start to operate normally, low temperature refrigerant liquid enters into shell (04) through refrigerant inlet, and it exchanges heat with water inside heat exchange pipe (06). After heat is absorbed and evaporated, it runs back to compressor through refrigerant outlet. Water in the tank (13) is pump out of water outlet (09) and delivered up to the inlet (03) of tank (01). After water goes across the distributive pipe (02), it downwardly flows along the wall of heat exchange tubes (06) and forms water film. The water then begin to exchange heat with the refrigerant outside the heat exchange tubes (05). When temperature lowers down, water freezes and ice formed inside heat exchange tubes (06)

Ice doffing process

As ice reaches a certain thickness, water route system stops circulation. Reduction gear (07) begins to run, and outside heat exchange tubes (05) is replaced by hot refrigerant gas which then melts the surface of ice. The ice harvests from heat exchange pipe (05) because of gravitational force and falls into ice cutter (08). Ice column finally is cut into 30-50mm length pieces of tube ice. Tube ice drops down and threw to ice outlet (12).

► Linsky Tube Ice Machine

Copyright © All rights are reserved by Linsky• Formulate future since 2004