Contact Us

- +86 21 57456563

- +86 21 57456583

- inquiry@linskyice.com

- Linsky direct system block ice machine uses aluminum alloy plate evaporator instead of traditional cooling media“brine”to make ice. Ice and refrigerant conduct heat transfer directly through aluminum alloy plate. In this way, machine can harvest ice within shorter time and effectively increase ice making efficiency and meanwhile, more energy is saving;

- All parts of Linsky direct system block ice machine which contact with water are made of SUS304 or aluminum alloy material. The produced ice is clean and hygiene, complying with HACCP certification requirement. Ice could be eaten directly.

Aluminum Direct Type Block Ice Machine Features

- Adopts latest technology, no need of brine tank;

- Aerospace aluminum alloy 6063-T5, high heat transfer coefficient, high strength and robust evaporator by enhanced welding technology;

- Direct heat exchange between the water and refrigerant in aluminum evaporator brings higher ice making efficiency, thus ice forms 1.5 times faster than ordinary ice machine which uses brine water;

- Easy-to-operate screw rod lifting mechanism gets feedback from the distance sensor which can realize more precise and safe control;

- Passive reservoir control method applied to specify precise liquid supply, which increases ice making efficiency and system reliability;

- Automatic water adding function by back type liquid level control technology;

- Silicone foam seal avoids evaporator dripping problem;

- Unique refrigeration system, using hot gas defrost technology makes easier and automatic ice harvest;

- Integrated modular design facilitates installation and maintenance on the spot;

- Food grade manufacturing process, totally complies with food standard;

- Warranty period

| Complete Package | 12~15 months |

| Compressor | 3 years |

| Evaporator | 3 years |

| Condenser | 3 years |

| Cooling Tower | 15 months |

How Does Aluminum Direct Type Block Ice Machine Work?

|

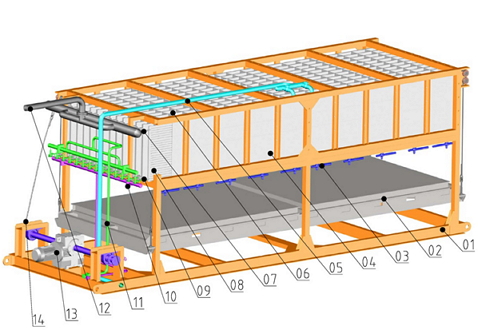

01: Steel frame |

* The diagram of aluminum direct system block ice machine working principle

As shown, Ice filling plate (02) will be elevated by wire rope (14) which is driven by speed reducer (13). Lift up the filling plate to be fastened in the lock handle (03) and get the whole aluminum alloy plate evaporator (04) sealed. Add water into the ice grid (06) automatically through water feeding pipes (05). At the bottom of all ice grid there is a 5mm space ensures water can flow through each ice can. When water reaches to the standard level, it will stop to continue to add water automatically.

Refrigeration system starts to run after water adding process. Refrigerant flows into the refrigerant runner (08) of aluminum evaporator (04) from refrigerant inlet (09) and exchanges heat with water in ice grid to lower the water temperature.

In a certain time, all the water in ice can will turn into block ice. At this time, refrigeration system switches to ice defrost mode. Hot gas enters into gas return tube (12) and becomes fluid in refrigerant runner (08), then back through liquid discharge tube (10) to the dry evaporator.

Hot gas defrosts ice surface and separates them from ice grid. At this time, refrigeration system stops to work. Speed reducer for lifting mechanism (13) drives wire rope to lower ice lifting plate to the bottom place of steel frame (01). The ice on filling plate can be manually moved away or the whole plate be taken away by forklift for swift and labor-free ice shift.

The Specification of Linsky Aluminum Direct Type Block Ice Machine

| Model | Capacity | Refrigerant | Operating Power | Install Power | Operating weight | Dimension |

|---|---|---|---|---|---|---|

| LIB-10D | 1ton/day | R22/R404A | 4.2kw | 5.4kw | 950kg | L2455XW935XH2018mm |

| LIB-20D | 2ton/day | R22/R404A | 7.2kw | 9kw | 1460kg | L4549XW1104XH1881mm |

| LIB-30D | 3ton/day | R22/R404A | 11.8kw | 13.8kw | 2280kg | L4300XW2100XH2050mm |

| LIB-50D | 5ton/day | R22/R404A | 18.9kw | 24.2kw | Unit:960kg | L2500XW1400XH1450mm |

| Evaporator:2260kg | L2910XW1855XH1900mm | |||||

| Cooling Tower:460kg | ∅1380XH2170mm | |||||

| LIB-100D | 10ton/day | R22/R404A | 34.8kw | 46.4kw | Unit:1680kg | L1800XW1600XH1800mm |

| Evaporator:3750kg | L5566XW1355XH2300mm | |||||

| Cooling Tower:670kg | ∅2000XH2410mm | |||||

| LIB-150D | 15ton/day | R22/R404A | 57.8kw | 73kw | Unit:2580kg | L2270XW2170XH2200mm |

| Evaporator:4680kg | L6520XW2170XH2420mm | |||||

| Cooling Tower:1120kg | ∅2175XH2565mm | |||||

| LIB-200D | 20ton/day | R22/R404A | 72kw | 96kw | Unit:2880kg | L3080XW2140XH2460mm |

| Evaporator:6540kg | L8385XW2145XH2480mm | |||||

| Cooling Tower:1300kg | ∅2650XH2645mm | |||||

| LIB-250D | 25ton/day | R22/R404A | 88.3kw | 120kw | Unit:3750kg | L3080XW2140XH2460mm |

| Evaporator:7560kg | L10195XW2160XH2741mm | |||||

| Cooling Tower:1630kg | ∅3050XH2780mm | |||||

| LIB-300D | 30ton/day | R22/R404A | 118kw | 145kw | Unit:4135kg | L3780XW2140XH2460mm |

| Evaporator:9840kg | L11890XW2160XH2741mm | |||||

| Cooling Tower:2730kg | ∅3300XH2785mm | |||||

| Standard condition: dry bulb temperature is 35℃ and inlet water temperature is 25℃. | ||||||

Note: Click the model number for details.

Copyright © All rights are reserved by Linsky• Formulate future since 2004