Flake Ice Machine

Contact Us

- +86 21 57456563

- +86 21 57456583

- inquiry@linskyice.com

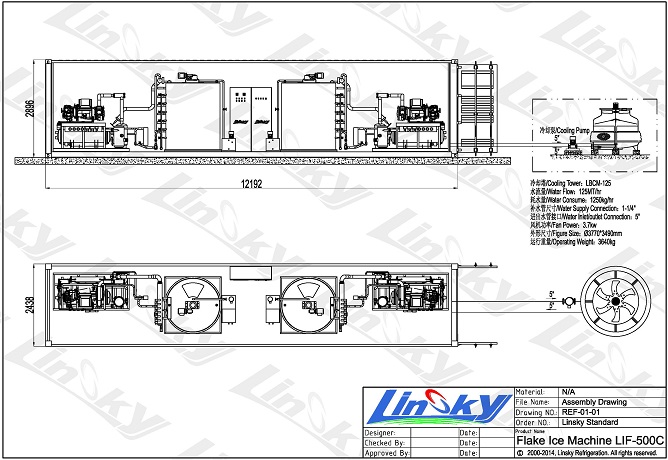

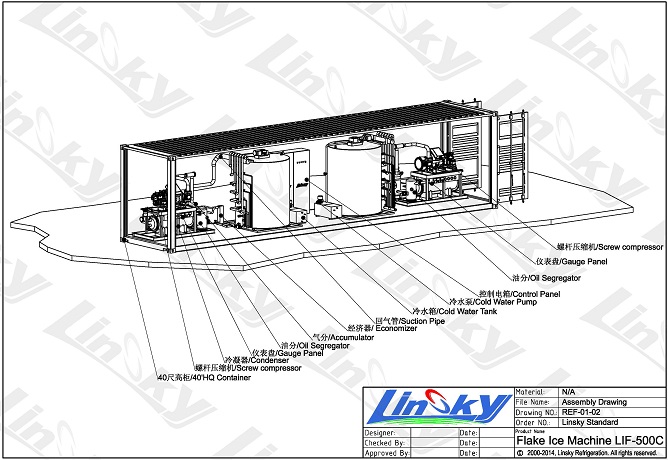

Flake Ice Machine LIF-500CHome > Products > Flake Ice Machine> Containerized Type

Home | Tube ice machine | Block ice machine | Flake ice machine | Plate ice machine | Cube ice machine | Accessories | Contact us

Copyright © All rights are reserved by Linsky• Formulate future since 2004