Block Ice Machine

Contact Us

- +86 21 57456563

- +86 21 57456583

- inquiry@linskyice.com

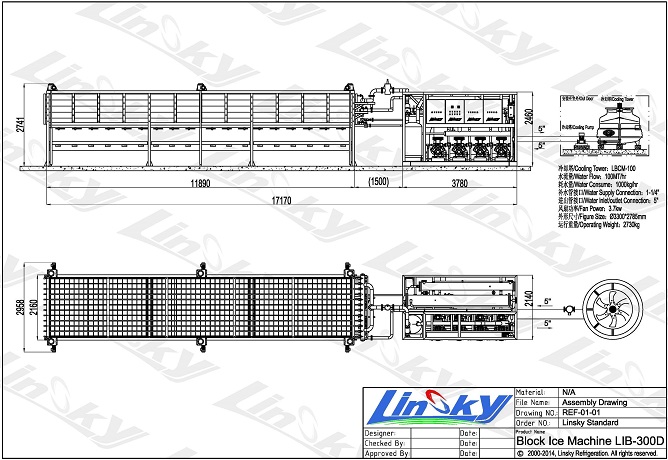

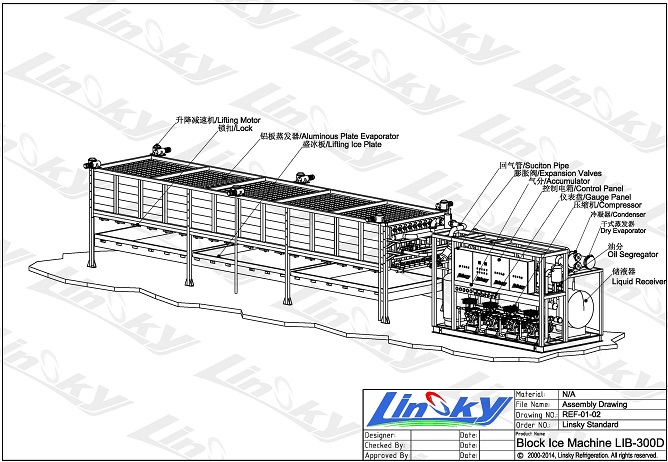

Block Ice Machine LIB-300DHome > Products > Block Ice Machine> Aluminum Direct Type

Home | Tube ice machine | Block ice machine | Flake ice machine | Plate ice machine | Cube ice machine | Accessories | Contact us

Copyright © All rights are reserved by Linsky• Formulate future since 2004